Fuse cutout is actually a short-circuit protector, which is mainly used for short-circuit protection or severe overload protection and is widely used in power distribution systems and control systems. The fuse is mainly composed of a melt and an insulating tube (insulating seat) for installing the melt. When in use, the melt is connected in series to the protected circuit. When the circuit has a short-circuit fault, the melt is instantaneously blown to break the circuit and play a protective role.

A simple working principle of fuse cutout: Is q = I2Rt; where Q is the amount of heat generated, I is the current flowing through the conductor, R is the resistance of the conductor, and t is the time the current flows.

There is a rating on each fuse, and the fuse will blow when the current exceeds the rating. When a current between the conventional non-fuse current and the rated breaking capacity (current) specified in the relevant standard acts on the fuse, the fuse shall work satisfactorily without endangering the surrounding environment. Fuses protect electronic equipment from overcurrent damage and also prevent serious damage to electronic equipment caused by internal faults.

First, the difference between fuse and circuit breaker

The same point is that they can achieve short-circuit protection. The fusing of the fuse is the result of the combined action of current and time, while the circuit breaker will trip as long as the current exceeds its set value, and the effect of time can hardly be considered. Circuit breakers are commonly used components in low-voltage power distribution today. There are also some places where fuses are suitable.

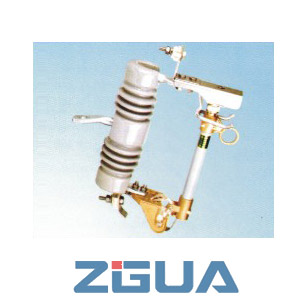

2. Common fuse cutout

1. Enclosed fuse

There are two types of enclosed fuses: filled fuses and unfilled fuses. Filled fuses generally use square porcelain tubes, which are filled with quartz sand and melt, and have a strong breaking capacity. They are used in circuits with voltage levels below 500V and current levels below 1KA. The non-packing closed fuse packs the melt into a closed cylinder, with a slightly smaller breaking capacity, and is used in power grids or power distribution equipment below 500V and 600A.

2. Fast fuse

It is mainly used for short-circuit protection of semiconductor rectifier components or rectifier devices. Due to the low overload capacity of semiconductor components. It can only withstand a large overload current in a very short period of time, so short-circuit protection is required to have the ability to quickly fuse. The structure of the fast fuse is basically the same as that of the enclosed fuse with filler, but the melt material and shape are different. It is a variable-section melt with a V-shaped deep groove punched by a silver sheet.

3. Self-resetting fuse

Self-recovery fuse is a new type of fuse element with overcurrent and overheating protection functions, which can be reused many times.

The structure principle of resettable fuse

The self-recovery fuse is a PTC thermal element with a positive temperature coefficient. It is made of a mixture of high molecular polymers and conductive materials. It is connected in series in the circuit and can replace the traditional fuse.

When the circuit is working normally, the self-recovery fuse is in a conducting state. When an overcurrent fault occurs in the circuit, the temperature of the fuse itself will rise rapidly, the polymer material will quickly enter a high resistance state after being heated, and the conductor will become an insulator, cutting off the current in the circuit and making the circuit enter a protection state. When the fault disappears and the self-recovery fuse cools, it is in a low-resistance conduction state and the circuit is automatically connected.

The action speed of the self-recovery fuse is related to the magnitude of the abnormal current and the ambient temperature. The larger the current and the higher the temperature, the faster the action speed.

3. Use and maintenance of fuse cutout:

1. When the melt is blown, carefully analyze the cause of the fuse. The possible reasons are:

1) Normal fuse due to short-circuit fault or overload operation.

2) The melt has been used for too long, and the melt has been broken by mistake due to the change of melt characteristics due to oxidation or high temperature during operation.

3) There is mechanical damage when the melt is installed, which reduces the cross-sectional area and causes false interruptions during operation.

2. When replacing the melt, it is required to do:

1) Before installing a new melt, find out the cause of the melted fuse. If the cause of the melt is not determined, do not replace the melt for test delivery.

2) When replacing a new melt, check whether the rating of the melt matches the protected equipment.

3) When replacing the new melt, check the internal burn of the fuse tube. If there is a serious burn, replace the fuse tube at the same time. When the porcelain melting tube is damaged, it is not allowed to replace with another material tube. When replacing the melt of the filler-type fuse, pay attention to filling the filler.

3. Fuse cutout should be repaired at the same time as the power distribution device:

1) Clean the dust and check the contact of the contact points.

2) Check the appearance of the fuse (remove the fuse tube) for damage and deformation, and whether the porcelain parts have discharge and flicker marks.

3) Check the fuse, and whether the melt matches the protected circuit or equipment, if there is any problem, it should be investigated in time.

4) Pay attention to checking the N line in the TN grounding system and the grounding protection line of the equipment, and fuses are not allowed.

5) When maintaining and inspecting the fuse, cut off the power supply according to the requirements of safety regulations, and do not allow the fuse tube to be removed with electricity.

Fourth, the use of fuse precautions:

1. The protection characteristics of the fuse should be compatible with the overload characteristics of the protected object. Considering the possible short-circuit current, select the fuse with the corresponding breaking capacity.

2. The rated voltage of the fuse should be adapted to the line voltage level, and the rated current of the fuse should be greater than or equal to the rated current of the melt.

3. The rated current of the fuses at all levels in the line should be matched accordingly, and the rated current of the melt of the previous level must be greater than the rated current of the melt of the next level.

4. The melt of the fuse should be matched with the melt as required. It is not allowed to increase the melt at will or replace the melt with other conductors.